Treating waste water from commercial kitchen sinks

What is a grease interceptor?

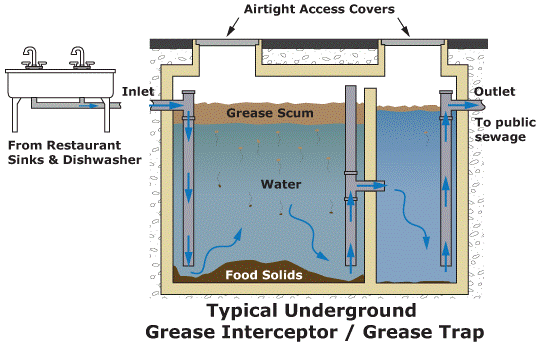

Grease interceptors were originally patented as passive gravity separators by Nathanial Whiting in the late 1800s. Grease interceptors are a device used to separate fats, oils, and grease (FOG) from wastewater.

When it comes to commercial kitchens, there is an abundance of solid food particles and FOG included in the sanitary discharge. Larger food solids should first be removed manually. As the discharge reaches the grease interceptor, the smaller particles sink to the bottom, while the lighter FOG rises to the top. The main function of the grease interceptor is to separate the FOG and release only the relatively grease-free water into the normal sanitary system.

Click here to learn how to size a grease interceptor?

Recovering and recycling grease

FOG entering the waste stream can create a problem for almost every community—both environmentally and economically. Not only does this cause concern for the water system, but the grease itself can no longer be recycled due to contamination from metals, chemicals, and pathogens. This is an unnecessary loss of a valuable resource. Metro Vancouver introduced a bylaw in 2012 that establishes maintenance requirements, and limits on how much grease and solids can flow into the sanitary system. Click on the link to see the details.

Grease can be recovered and recycled. If recovered before entering the waste water system, the grease can be recycled into a variety of products including fertilizer, animal feeds, soaps, and cosmetics. However, if the grease is not collected early on, it can remain trapped for long periods of time and will no longer be suitable for further use. Trapped grease is referred to as brown grease, and must be disposed of properly. Typically, brown grease is pumped from interceptors by grease pumping trucks. Fortunately, positive developments are in progress for ways to recycle brown grease.

Preventing blocked sanitary pipes

Grease can block pipes as it forms grease encapsulated solids. When grease becomes very hard, it becomes a ball or aggregate, leading to blockage problems within pipes and waste water collection systems. Rotting food stuck within pipes run the risk of producing toxic waste such as sulfur gases, not to mention degradation of the pipes themselves.

Through using a grease interceptor, the grease is separated from the waste water prior to entering sanitary pipes. This alleviates the concern of blockage, while preventing the unnecessary waste of usable grease. This also reduces the chances of sewer pipe blockages which are a leading cause of sewer overflows—an issue that concerns the entire municipality.

Aiding operation at water treatment plants

Waste water that is ridden with FOG is very difficult to manage at water treatment plants. An increase in time and cost can be expected as more resources are required. These setbacks affect all wastewater collection systems and water treatment plants, regardless of size or capacity. Private wastewater collection systems will incur high costs in repair in replacement. Larger systems will experience even greater costs, as well as a longer timeline for repair.

Grease interceptors were developed to make the water treatment process go over more smoothly, with cost-effectiveness in mind. Most of the ground work is completed before the waste water reaches the treatment plant, thereby reducing the problems and associated costs at the plant. By treating the waste water in advance, the municipal sewer infrastructure is also protected from harmful outflow.

Investing in a grease interceptor

Every commercial kitchen can benefit from an effective grease interceptor. Grease interceptors use gravity and coalescence to separate FOG which is approximately 89–90% the weight of water. The separation chamber lets FOG rise to the surface, and the FOG-free water flows out of the chamber. With the use of a grease interceptor, grease can be effectively separated from waste water before it has a chance to cause any damage. The grease also has a chance to be recycled into new products, promoting a sustainable and environmentally-sound approach to waste water management.

Recent Comments